Mizutani Laboratory

Dept of Applied Biochemistry, School of Engineering, Tokai University

Home -

Movies/3D models -

Publications -

MCTrace -

RecView

-

RecView -

3D test patterns

-

3D test patterns

Three-dimensional test patterns for micro-CT and nano-CT

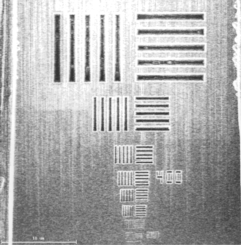

In order to estimate the spatial resolution of 3D images taken with microtomography (micro-CT) or nanotomography (nano-CT), we use test objects on the submicrometer to nanometer scale prepared by focused-ion-beam milling (FIB). The resolutions along the direction within the tomographic slice plane (in-plane or transverse resolution) and perpendicular to it (through-plane or sagittal resolution) can be determined from their square-wave patterns. The aluminum test patterns are labile in the air when it's stored for a long period, such as over one year. If possible, they should rather be stored in a vacuum chamber.

Micrometer to submicrometer patterns

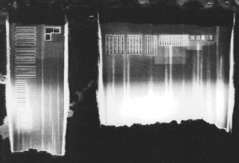

Test pattern 080425AL

Material: aluminum wire, 0.25 mm diameter.

Material: aluminum wire, 0.25 mm diameter.

Pattern pitches: 2.0, 1.6, 1.2, 1.0, 0.8, 0.6, 0.5, 0.4, 0.3, 0.2 um.

Resin embedded.

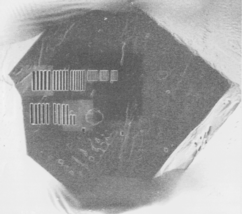

Test pattern 080604D1

Material: diamond, ca. 0.15 mm crystal.

Material: diamond, ca. 0.15 mm crystal.

Pattern pitches: 2.0, 1.6, 1.2, 1.0, 0.8, 0.6 um. In-plane only.

Nanometer patterns

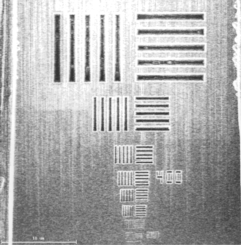

Test pattern 130315AL

Material: aluminum rod, ca. 0.12 mm square.

Material: aluminum rod, ca. 0.12 mm square.

Pattern pitches: 2.0, 1.0, 0.5, 0.40, 0.35, 0.30, 0.25, 0.20 um, 180, 160, 140, 120, 100, 90, 80 nm.

Test pattern 130524AL

Material: aluminum wire, 0.10 mm diameter.

Material: aluminum wire, 0.10 mm diameter.

Pattern pitches: 2.0, 1.0, 0.5, 0.40, 0.35, 0.30, 0.25, 0.20 um, 180, 160, 140, 120, 100, 90, 80 nm.

References

- R. Mizutani, A. Takeuchi, R.Y. Osamura, S. Takekoshi, K. Uesugi and Y. Suzuki (2010). Submicrometer tomographic resolution examined using a micro-fabricated test object. Micron 41(1), 90-95.

DOI

PubMed

arXiv

- R. Mizutani, K. Taguchi, A. Takeuchi, K. Uesugi and Y. Suzuki (2010). Estimation of presampling modulation transfer function in synchrotron radiation microtomography. Nuclear Instrum. Meth. A 621(1-3), 615-619.

DOI

arXiv

Document

A PDF document of these test patterns is

here. You can find close-ups of the test patterns in it.

Contact

If you would like to use these test patterns at SPring-8, please contact:

Ryuta Mizutani, Dr.

Department of Applied Biochemistry, Tokai University

Kitakaname 4-1-1, Hiratsuka, Kanagawa 259-1292, Japan

E-mail mizutanilaboratory(at)gmail.com

Home -

publication -

movies/models -

MCTrace -

RecView

-

RecView -

test patterns

-

test patterns

Our lab pages at GitHub /

YouTube

MizutaniLab -

Dept of Applied Biochemistry -

Sch of Engineering [jpn]

-

Sch of Engineering [jpn] -

Tokai Univ

-

Tokai Univ

Material: aluminum wire, 0.25 mm diameter.

Material: aluminum wire, 0.25 mm diameter. Material: diamond, ca. 0.15 mm crystal.

Material: diamond, ca. 0.15 mm crystal. Material: aluminum rod, ca. 0.12 mm square.

Material: aluminum rod, ca. 0.12 mm square. Material: aluminum wire, 0.10 mm diameter.

Material: aluminum wire, 0.10 mm diameter.